Course Search Results

Course Search Results

Course Name

Interlocking Solid State FLMFCourse Description

At the end of the training the delegate will be able to describe: Engineering specifications associated with the specific type of electronic based interlocking. How the maintenance, faulting, repair and testing activity may affect the safe operation of the railway. What procedures need to be followed to ensure operational and personal safety is maintained during the work. How to avoid personal injury during the work. How the electronic based interlocking is designed to function under normal operating conditions.Audience

Successfully completed the Signal Engineering Maintenance 2 course. Had at least 6 months workplace experience.Following completion of the training each delegate shall undertake a period of mentored workplace experience to enable the learning to be consolidated through practical workplace experience.Duration:

5 Day(s)Class size:

6

Course Name

Interlocking Solid State FLMFCourse Description

<p>At the end of the training the delegate will be able to describe: Engineering specifications associated with the specific type of electronic based interlocking. How the maintenance, faulting, repair and testing activity may affect the safe operation of the railway. What procedures need to be followed to ensure operational and personal safety is maintained during the work. How to avoid personal injury during the work. How the electronic based interlocking is designed to function under normal operating conditions.</p>Audience

Successfully completed the Signal Engineering Maintenance 2 course. Had at least 6 months workplace experience.Following completion of the training each delegate shall undertake a period of mentored workplace experience to enable the learning to be consolidated through practical workplace experience.Duration:

5 Day(s)Class size:

6Competence Name Awarded:

Undertake corrective and preventative maintenance of Electronic Based Interlocking. Undertake corrective and preventative maintenance of Electronic Based Interlocking.SSI central interlocking Undertake corrective and preventative maintenance of Electronic Based Interlocking.SSI TracksideCompetence Awarded:

Sig 19; Sig 19.08a; Sig 19.08bCourse Code:

STF 140Prerequisite Name:

Undertake corrective and preventative maintenance of Track Circuit, Electrical Signals including AWS and TPW, Signalling Power Supplies and Signalling Cables. Take and relinquish responsibility for Signalling equipment. Ensure effective progression of work and use of resources during signalling testing, maintenance or installation activities.Prerequisite Short Code:

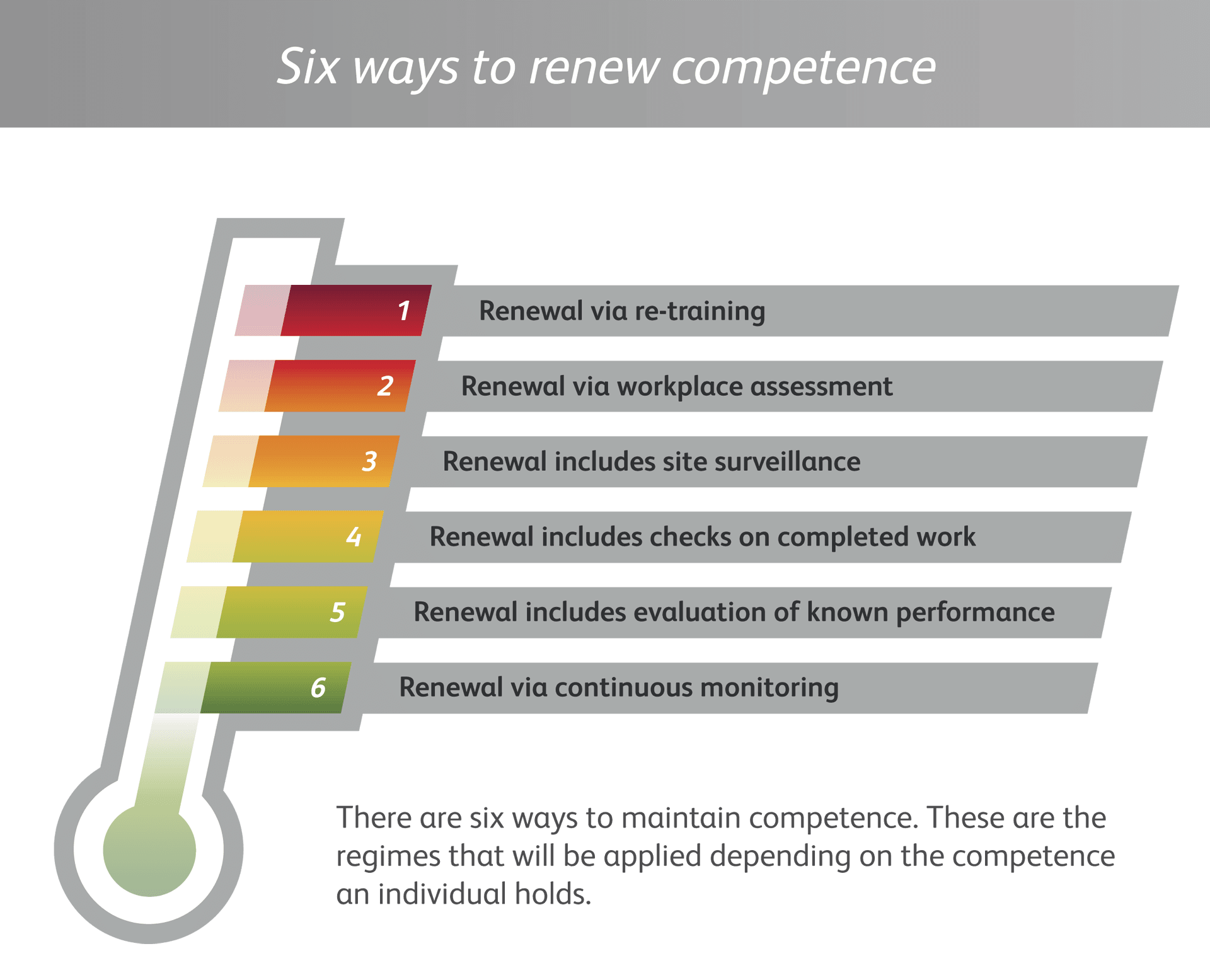

Sig 05; Sig 07; Sig 13; Sig 14; Sig 23; Sig 24; Sig 25Skills Assessment Scheme Regime:

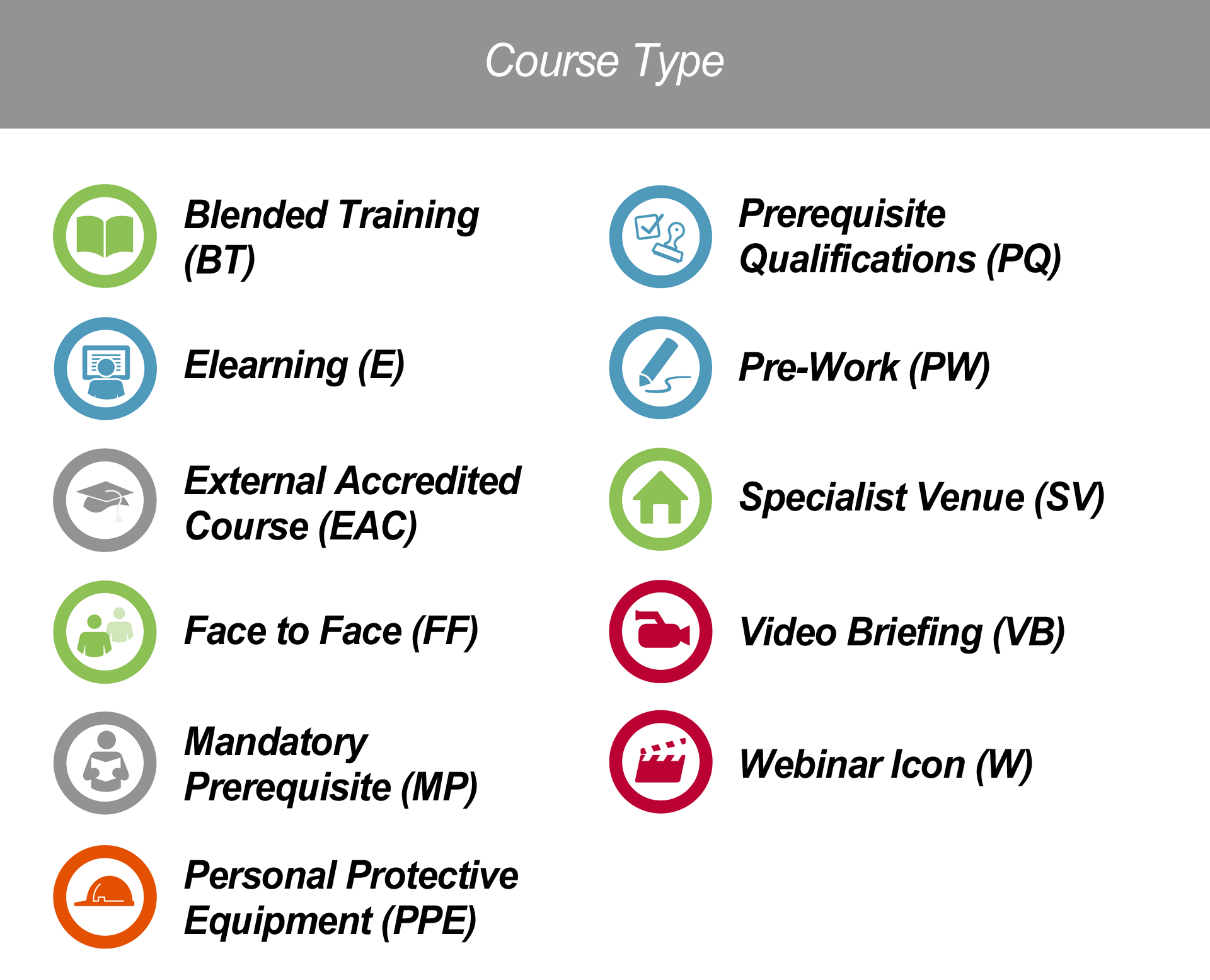

6Course Type:

Course Name

Interlocking Solid State FLMFCourse Description

<p>At the end of the training the delegate will be able to describe: Engineering specifications associated with the specific type of electronic based interlocking. How the maintenance, faulting, repair and testing activity may affect the safe operation of the railway. What procedures need to be followed to ensure operational and personal safety is maintained during the work. How to avoid personal injury during the work. How the electronic based interlocking is designed to function under normal operating conditions.</p>Audience

Successfully completed the Signal Engineering Maintenance 2 course. Had at least 6 months workplace experience.Following completion of the training each delegate shall undertake a period of mentored workplace experience to enable the learning to be consolidated through practical workplace experience.Duration:

5 Day(s)Class size:

6Competence Name Awarded:

Undertake corrective and preventative maintenance of Electronic Based Interlocking. Undertake corrective and preventative maintenance of Electronic Based Interlocking.SSI central interlocking Undertake corrective and preventative maintenance of Electronic Based Interlocking.SSI TracksideCompetence Awarded:

Sig 19; Sig 19.08a; Sig 19.08bCourse Code:

STF 140Prerequisite Name:

Undertake corrective and preventative maintenance of Track Circuit, Electrical Signals including AWS and TPW, Signalling Power Supplies and Signalling Cables. Take and relinquish responsibility for Signalling equipment. Ensure effective progression of work and use of resources during signalling testing, maintenance or installation activities.Prerequisite Short Code:

Sig 05; Sig 07; Sig 13; Sig 14; Sig 23; Sig 24; Sig 25Skills Assessment Scheme Regime:

6Course Type:

How to Book